Summary

Truckers Are in for a Sea Change

Changes that happen slowly are changes nonetheless, and a decade-long shift in over-the-road trucking from human drivers to robotic ones will have important consequences. The trucking industry is now clearly moving toward autonomous vehicles on a schedule that will allow robots to displace a well-defined and moderately well-paid group of individuals between 2022 and 2040. This extended time period is sufficient to mask the loss of 600,000 jobs, but the impact of those losses on employment, wages, taxes, and self-esteem will be important, nonetheless.

Introduction

“…the trucking industry is poised for a second great disruption when self-driving over the road trucks and local delivery systems replace millions of human drivers.” AhiRE/TaxRobots.org, May 14, 2016

Since the Alliance for Humans in a Robot Economy (AHiRE) began looking at trucking as an industry ripe for automation in 2016, technological progress has brought the first automated trucks to the brink of deployment. TuSimple, one of the developers of autonomous truck technology, reported they had “completed the world’s first fully autonomous semi-truck run on open public roads without a human in the vehicle, and without human intervention” on December 22nd, 2021.

This demonstration showed that the autonomous tractor is capable of co-existing with human drivers on the open highway.

Discussion and Analysis

Terminology for Purposes of this Discussion

Trucking, like most industries, has a language of its own. While much of this language consists of colorful or slang expressions, there are terms of art that may have interchangeable or imprecise meanings and currently lack formal definitions. The following terms used throughout this paper are described in general terms developed by the author for the purpose of this discussion.

Figure 1. Tractor-trailer. Credit: clipart-library.com/cii-part/truck-transparent-background-7.html

Tractor-trailers are the large trucks that are used to transport big loads over long distances. These truck systems generally consist of a powered tractor towing one or more trailers using an attachment mechanism referred to as a fifth wheel (Figure 1). The word “tractor” is used throughout this discussion because it is the portion of the truck system where, in the current state of the art, it is where self-driving sensors and computing technology are installed.

The fifth wheel attachment system integrates the trailer with the tractor so completely that it is often referred to as a “semi-trailer.”

Autonomous tractors operate without a human being present in the vehicle.

Human-operated tractors are operated exclusively by an onboard human driver.

Duty cycle is the ratio of the time the tractor is operating divided by the total time available. Since there are 168 hours in a 7-day week, a human driver working a 40-hour week operates the vehicle for 40/168 or a 0.238 duty cycle.

Over the road refers to a route requiring a human driver to spend one or more nights away from home.

Long haul is a term that has been used to refer to a hauling distance of 250 miles (and includes over the road as defined above). For this article, long haul refers to a drive of sufficient distance to economically justify the cost of transferring a load from a human-operated tractor to an autonomous tractor at the beginning of the haul and from the autonomous tractor to a human-operated tractor at the end of the haul.

Transfer hub. A location where load transport control is shifted from a human-operated tractor to an autonomous tractor or from an autonomous tractor to a human-operated tractor.

Affected Workers

A widely reported recent study published on Nature.com indicates that 90% of long-haul trucking jobs, or 500,000 truck drivers, could be replaced by autonomous tractors. The study also indicates that about 550,000 long-haul driving jobs exist.

According to the Nature article, multiple organizations are working to implement autonomous trucks in the near future by using a transfer hub system that would divide the driving effort by the extent of difficulty. Fully autonomous tractors would move trailers on limited-access highways and in good weather. In contrast, tractors with human drivers would handle the more complicated operations on local roads. Load transfer locations, possibly as simple as a large, paved surface, would provide a location for shifting a load from one tractor to another. This could be accomplished simply by having a human truck driver enter the cab and take control of the tractor.

According to the federal Bureau of Transportation Statistics, semi-trucks in the United States traveled an average of 175 billion miles annually between 2007 and 2020. If that rate continues and 75% of those miles are on limited-access highways that have traffic conditions, weather patterns, and roadway characteristics that are compatible with early self-driving technology, about 130 billion of those miles could be driven by autonomous tractors in the near future. If those tractors travel at 65 miles per hour, it will take them approximately two billion operating hours to travel such a distance.

Tractor operating hours and truck driver working hours are equivalent. Thus, two billion tractor operating hours equals two billion truck driver working hours. If the average long-haul truck driver works about 2,800 hours per year (by law, they are allowed to drive up to 11 hours per day), this equates to about 720,000 long-haul tractors and 720,000 truck drivers during a typical year.

For the purposes of this analysis, we assume that there are about 600,000 truckers and tractors in active, full-time service on long-haul routes using limited-access highways in the United States in 2022. While this number is lower than that derived through analysis but greater than that reported in the Nature study, it is a midpoint that is adequate for use in this paper.

We note that this analysis ignores double and triple trailer arrangements under the assumption that, while they might or might not be suitable for attachment to autonomous tractors, they are a small percentage of the long-haul truck universe.

Factors Slowing the Transition to Autonomous Truck System Operations

Those 600,000 trucker jobs will not disappear instantly. The transfer hub strategy for the initial deployments of autonomous tractors was chosen to place the first of those autonomous vehicles in the least challenging driving conditions available. Success on the “easy routes” will provide increased confidence in deploying the technology on “slightly harder” routes, where success will encourage further implementation. This step-by-step approach will slow the transition of long-haul trucking from manually controlled tractors to autonomous ones.

There are at least three factors that will slow the deployment of autonomous tractors.

- Highway design and location. All limited-access highways are not equally suitable for autonomous tractor operation. The flat, open terrain of the American Midwest makes for long, straight stretches of highway with limited traffic, while urban beltways often combine frequent curves and interchanges with heavy traffic and wide variations in driver behavior. Mountainous terrain requires anticipating and addressing sharp turns as well as severe up and downgrades.

It seems likely that autonomous tractor introduction will take place in locations that present the fewest operator challenges.

- Time of day. The time of day is also a factor for autonomous tractors that use visible light as a major sensor input. Such sensors are affected by the bright light of noon, the darkness of midnight, and the glare of sunrise and sunset, just as human eyes are. The difficulties associated with other traffic vary over the diurnal cycle as well.

It seems likely that autonomous tractor operation will be implemented at first in lighting conditions well suited to the sensor suite the autonomous controller uses to control the tractor. We note, however, that autonomous tractors are likely to more compatible with night operation than human-operated tractors because ambient light camera designs can be adapted to work across a wider range of light wavelengths than the human eye can perceive and to respond to light intensities well below those the human eye can see.

- Weather. The difficulties presented by bad weather conditions in various parts of the United States vary widely and, using tornadoes as an example, can change from benign to extremely hazardous suddenly. Patchy fog and snow showers can cause visibility to drop both severely and suddenly.

The weather can also combine with local terrain, high winds in mountainous areas, for example, to create extremely difficult driving conditions.

It seems likely that autonomous tractor operation will be first introduced in benign weather conditions to minimize the challenges the autonomous tractor must overcome.

We note, however, that camera’s ability to respond to light wavelengths beyond those to which the human eye is sensitive is likely to allow them to be tailored for low-visibility weather conditions such as fog or rain. This would serve to increase the autonomous tractor’s available duty cycle and, therefore, its productivity.

Gradual Autonomous Tractor Introduction

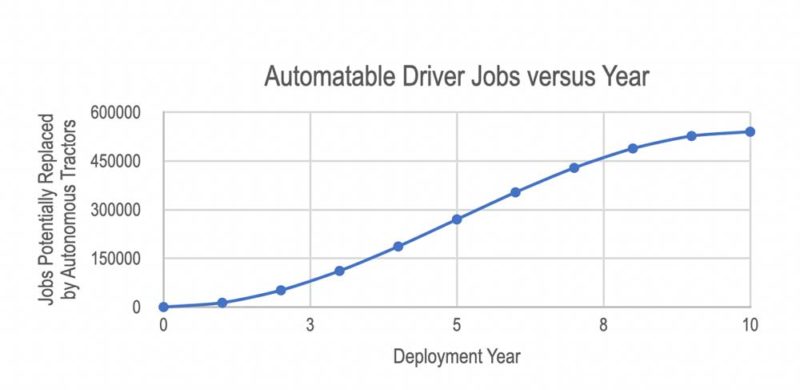

Figure 2. The number of jobs threatened by autonomous tractors is likely to rise at changing rates.

Each of the factors listed will tend to make the introduction of autonomous tractors gradual rather than sudden. Thus, it seems reasonable to conclude the driver jobs that are replaced on limited-access highways as increasing slowly at first, then rapidly, then slowly, and becoming static when some “final” level as illustrated by the notional graph in Figure 2.

Tractor Service Life

Heavy-duty tractors go through a service life that typically begins with a new tractor delivered to a large trucking company, then operated by that company for years, and finally sold in a secondary market in which smaller companies and owner-operators purchase the used but still fully functional, tractors. The tractor’s initial operational life ends at an “economically optimal” time anecdotally defined as about 500,000 miles or five years after the initial purchase. While specifics vary significantly from company to company, the factors in the timing of this first resale into the used tractor market include but are not limited to engine wear, taxes, maintenance expenses, and available financing.

If long-haul operations are dominated by large firms, there are approximately 600,000 semi-truck tractors being used by them, and those tractors have an average service life of 5 years; new trucks would replace the existing ones at a rate of about 120,000 tractors per year. This represents the maximum likely number of autonomous tractors placed into service each year.

According to Statista, roughly 230,000 Class 8 trucks are produced in a typical year. The Class 8 designation includes over-the-road tractors as well as a variety of other heavy-duty trucks such as dump trucks and smaller vehicles such as delivery vans. If 50% of the Class 8 trucks enter service as long-haul tractors, the rate of replacement would be 115,000 tractors per year. This agrees well with the above analysis.

Based on this data, the service life of a typical long-haul tractor is assumed to be characterized by:

- from initial purchase to five years, it operates in high-intensity, long-haul service;

- from five to 10 years after initial purchase, it operates in medium-intensity, short- to medium-haul service; and

- from 10 to 15 years after initial purchase, the last of the tractor’s value is extracted in low-intensity local service.

Factors Affecting Autonomous Tractor Introduction

If all the replacement tractors entering service were fully autonomous designs, it would take approximately five years to replace the long-haul rolling stock, but this is very unlikely for multiple reasons.

Life-cycle cost model. First, there is the financial calculation to be made by the large companies. Tractors are expensive, costing on the order of $120,000 each in 2020. This initial cost and the expected value to be recouped when the tractor is sold into secondary operations are well known and central to the companies’ cost models.

If the autonomous driving capability is added to the basic tractor, the purchase cost might increase by about $20,000. If driver accommodations such as air conditioning and roll cages are eliminated, the purchase cost might decrease by an equal or greater amount. There is, however, no historical data on which to base an estimate of how these decisions will affect the tractor’s value on entering secondary service because this has never happened. Thus, the large company’s investment decision, especially in the early transition phase to autonomous tractors, will be made with significant uncertainty in its cost model.

That uncertainty creates a risk with a high cost and profitability impact that cannot be closed for approximately five years after the initial purchase. It is likely that the large companies will mitigate this risk by implementing autonomous tractors slowly.

Other infrastructure. The transfer hub system requires three significant elements: the autonomous tractor, the human-operated tractor, and the infrastructure for transferring the load from one to the other. Such infrastructure can take several forms, the simplest of which would be a small, open parking area where a human tractor operator would exit a tractor capable of both manual and autonomous operation and allow it to proceed under internal control or vice versa. More sophisticated versions could switch the load by removing the trailer from one tractor using the fifth wheel and attaching it to the second tractor in the same fashion, driver-waiting accommodations, lifts to switch containers from one trailer to another, or even warehouse space. The scale and complexity of this infrastructure will significantly affect load shifting and, therefore, autonomous tractor productivity.

There is no historical data showing what economically optimized autonomous tractor support infrastructure will consist of, exactly what it will cost, or how specific features will affect autonomous tractor productivity. This lack of historical information will create uncertainty in autonomous tractor operational cost modeling, thus increasing the cost/profit impacts of the autonomous tractor’s financial risk.

Creating this supporting infrastructure is also a significant barrier to quick implementation because each site will be unique and require land purchase, engineering design and permitting, and investment in constructing the facilities. The cost and schedule uncertainties involved in creating this infrastructure will create additional risks with cost and schedule consequences that could affect customer service as well as profitability. This, again, will tend to slow autonomous tractor implementation.

This combination of required investment and risk will cause the actual implementation of autonomous tractors to lag the maximum potential implementation rate, as illustrated by the notional delays shown in Figure 2.

Timeline for Driver Displacement

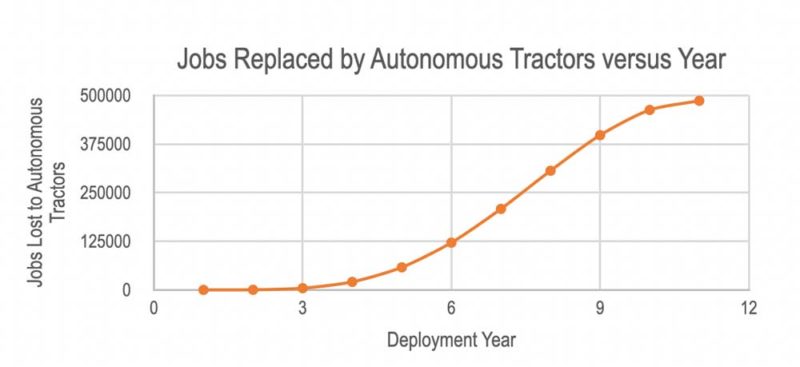

Figure 3. The expected driver job losses lag the implementation opportunity.

The time frame for the displacement of the current driver population will be affected by diverse factors.

Driver jobs affected per autonomous tractor. One of the many touted benefits of autonomous tractors is that they can operate continuously, 24 hours per day and seven days per week, within limits imposed by fuel, maintenance requirements, and external conditions such as weather. If maintenance reduces that availability from 100% to 90% and operational requirements such as fueling and load shifting impose a similar loss of availability, each autonomous tractor would be expected to operate approximately 7,000 hours per year.

A typical long-haul driver can reasonably be expected to drive about 2,800 hours per year, as described above. Thus, a single autonomous tractor would potentially replace approximately 2.5 drivers rather than one. While this is likely to be limited initially by external factors such as transfer station facilities and their services, it seems likely that driver job losses will be double or more than the number of autonomous tractors deployed.

Current driver shortage. Current estimates indicate that there is a shortage of about 80,000 truck drivers nationwide. It is not clear, however, what part of these drivers operate long-haul vehicles versus any of the other tasks the remainder of the nation’s 3.5 million truck drivers perform. For the purposes of this analysis, we assume that 50%, or 40,000 drivers, of this driver shortage applies to the long-haul, over the road traffic on limited-access highways. That equates to approximately 5% of the current population estimate of 600,000 over the road drivers.

This shortage will insulate those drivers currently working from the job losses caused by the autonomous tractors. It is also likely that the factors that contribute to the driver shortage, such as the constantly away from home lifestyle and technology changes, will continue to cause some working drivers to leave the profession voluntarily. This, too, will insulate the current driver population from the effects of autonomous tractors. Finally, the truck driver workforce is aging, with an average age of 55 years, and has an above-average rate of worker loss to retirement.

Conclusion

Autonomous tractors will eliminate approximately 500,000 long-haul truck driver jobs over approximately the next 15 years. This will occur so slowly that few drivers will be personally affected, which, in turn, will mitigate the anger that would result from a sudden loss of similar scope.

The result, however, will be profound.

In 2018, entry-level drivers earned “around $50,000 a year depending on what part of the business they go in. So it’s a good job. It pays well; you can build a family around it.”

The loss of these jobs will have an impact on our economy. The average pay of approximately $54,900 per year and 600,000 drivers combines to produce a total of 33 billion dollars in earnings, earnings that will not be a part of the United States’ economy. That 33 billion equates to about $5 billion in Social Security and Medicare taxes, taxes that would help to pay for benefits many senior citizens depend on. They, too, will be lost.

________________________________

* While there are specific cases of two drivers per truck – which is called “team driving,” increases asset utilization rates, and reduces transit time – this system is relatively rare and is ignored in this analysis.

- https://www.ahire.org/truckers-as-an-example/

- https://ir.tusimple.com/news-releases/news-release-details/tusimple-becomes-first-successfully-operate-driver-out-fully#:~:text=SAN%20DIEGO%20%2C%20Dec.,vehicle%20and%20without%20human%20intervention

- https://www.smart-trucking.com/trucking-terms/

- Mohan, A., Vaishnav, P. Impact of automation on long haul trucking operator-hours in the United States. Humanit Soc Sci Commun 9, 82 (2022). https://www.nature.com/articles/s41599-022-01103-w

- https://www.bts.gov/content/us-vehicle-miles

- https://www.fmcsa.dot.gov/sites/fmcsa.dot.gov/files/docs/Drivers%20Guide%20to%20HOS%202015_508.pdf

- https://www.statista.com/statistics/245369/class-8-truck-sales-by-manfuacturer/

- https://journals.sagepub.com/doi/full/10.1177/0361198120930228

- https://www.npr.org/2018/01/09/576752327/trucking-industry-struggles-with-growing-driver-shortage

- https://www.comparably.com/salaries/salaries-for-long-haul-truck-driver